Anyone who enjoys the global delicacy that is seafood knows this: It’s a very high-maintenance food item. The delicious taste of fish, lobster, shrimp, scallops, and other types of seafood is only brought out by delicate handling throughout the procurement, shipping, and cooking processes. From keeping crustaceans alive inside insulated shipping boxes to maintaining appropriate temperatures to reduce spoilage, there are many steps to ensure the safety of these food items.

Any cold chain packaging consultant will tell you that many customers end up losing their expensive seafood simply because they don’t opt for the right type of refrigerant during the shipping process. Temperature controlled shipping boxes are significant in some scenarios. Still, there are times when a more versatile, efficient, and cost-effective cooling source is needed to maintain the appropriate environment for seafood. Whether they are live or just need to be maintained, gel packs represent the perfect option for effectively shipping these delicacies without damage or spoilage.

Gel Packs and Insulated Shipping Boxes — The Perfect Cold Chain Combo

When it comes to passive cold chain shipping options, it’s hard to beat the combination of insulated boxes and cooling gel packs. Traditional refrigerants like ice often melt during longer hauls, damaging both the product and the packaging solution. On the other hand, gel packages maintain their temperature for longer, are more efficient at cooling and don’t cause any mess as their temperature increases.

General recommendations for using gel packs to maintain fresh seafood are as follows: Cooling a cubic foot of space for one day requires a pound of gel packages. Compared to options like ice packs and regular ice, this refrigerant takes up less space. This is ideal for situations where expensive, temperature- and time-sensitive items like seafood are being shipped over long distances.

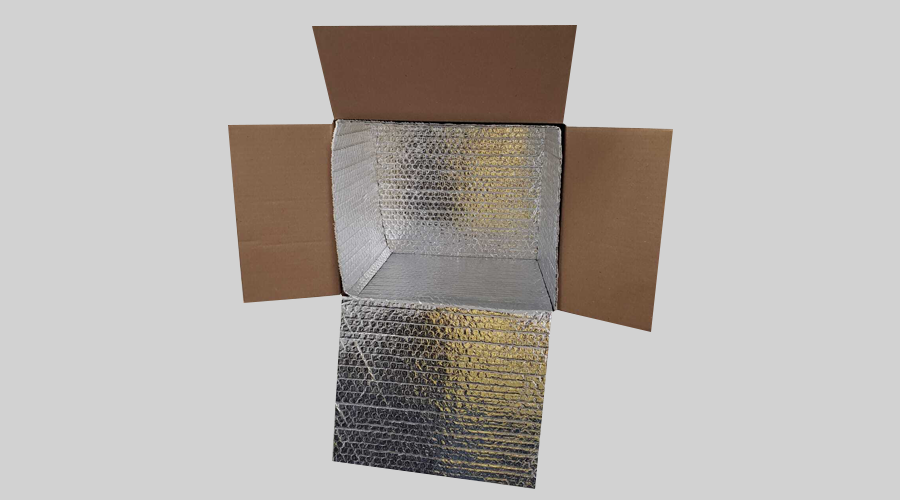

But that’s only half the battle when it comes to keeping fish, octopi, and crustaceans at the right temperature. Passive cold chain transportation necessitates properly insulated shipping boxes for the operation to be a success. Whether they are Styrofoam , insulated bubble foil or some other insulating material, these boxes ensure minimal heat loss during the journey. This helps to maximize the productivity of your gel packs, and products are all maintained at the desired temperature.

Cold Chain Shipping Companies

When it comes to selecting your cold chain packaging consultant, you don’t want to entrust your products to just anyone. Unlike normal shipping, which can handle some disruption to delivery times, cold products have a much slimmer margin for error. At Distinctive Solutions, we have extensive experience in improving the efficiency and quality of cold chain shipping for companies across a variety of different industries. For more information about our services, reach out to us today!