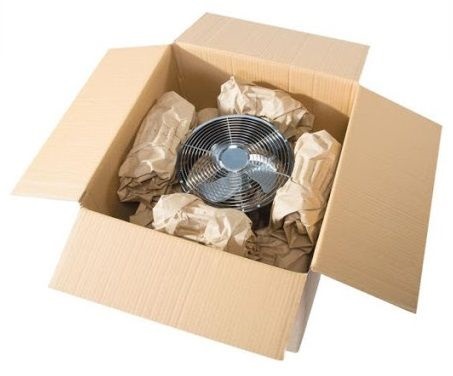

The increase of e-commerce means that items shipped in boxes with a less-than-perfect fit can lead to shifting, resulting in damaged or broken goods. This necessitates inspection of the goods for any broken parts and then sourcing a replacement part, a process that costs both time and money. A foam-in-place packaging system is an excellent cushioning and void fill packaging choice that can sometimes be recycled

How Foam-In-Place Packaging Offers Protection

This advanced packaging system works by creating custom foam molds that anchor products in place during shipping to ensure that they arrive intact. Additionally, these types of void fill packaging materials provide a durable shell that offers further protection to the item inside.

How It Works

The foam-in-place void fill packaging system uses “A” and “B” liquid components that are blended through a self-cleaning dispensing system. Operators then follow the steps outlined below:

1. The operator places a strong piece of PE film in the bottom of the shipping container

2. A layer of foam is then poured onto the film

3. At this point, the “A” and “B” components, which are urethane-based, react. This increases their volume by 280 percent and causes it to combine into a solid piece

4. Next, the foam begins to rise. The worker creates the initial level of the pack by folding over the plastic film

5. Now the delicate item is placed into the carton, on top of the folded liner

6. The foam rises further and expands around the item, eliminating any empty space

7. An additional foam layer is then added, and the process is repeated to create the upper shell

This void fill system has the added benefit of taking up very little floor space. It’s an excellent solution for delicate items that require something more durable than void fill paper packaging.

Benefits

The benefits of foam-in-place packaging are many. First and foremost, the protective shell provides both additional support and strength for the items being shipped. Second, the added protection makes it possible to downgrade to a single-walled rather than a double-walled cardboard box, which translates into savings.

Distinctive Solutions is the answer to all your void fill packaging needs. Call us today to discuss your particular requirements.